TRASH RACKS

Ideal for use in a variety of environments and industries, our trash racks will help your company screen debris from your intake water. Our trash racks prevent harmful debris from reaching your expensive equipment.

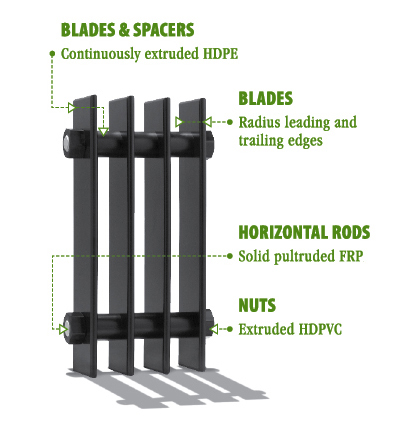

HCS Trash Rack Features

HCS’s trash racks with continuously extruded HDPE blades are rust-and corrosion-free, lightweight and easy to clean. The blades feature radius leading and trailing edges which reduce the resistance to the flow of water through the rack. Unlike metal trash racks, HCS trash racks will never need recoating.

Additional features of HCS trash racks include:

- Do not allow frazil ice to adhere or anchor ice to form

- Fully assembled and ready for installation when delivered

- High impact strength

- Resists zebra mussel fouling

- Improves water passage to turbine units and pumps

- Easy to maintain

HCS Trash Rack Applications

HCS trash racks prevent harmful debris from reaching your expensive equipment and are a vital part of your water intake system. HCS trash racks serve many different types of industries, including:

- Power generation

- Pulp, paper & steel mills

- Municipal water intakes

- Wastewater treatment plants

- Flood control pump stations

- Waterparks

- Custom applications

Other Trash Rack Products

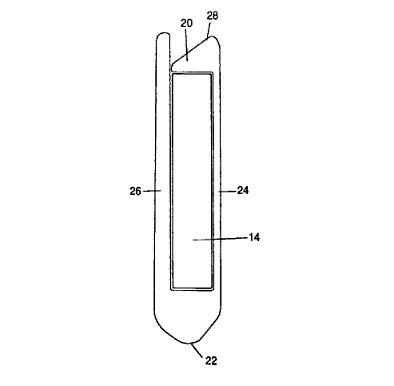

Patented Protective Sleeve for Intake Rack Bars

HCS protective sleeves, made from extruded HDPE, snap over existing metal rack bars providing many of the benefits of fully non-metallic rack assemblies, such as preventing anchor ice formation.

U.S. Patent No. 7,919,003 and 8,075,787.

Metal rack blade (14)

Protective sleeve (20) – made of extruded HDPE

Radiused leading edge (22) – thicker material to resist impact

Side walls (24 and 26) – thinner material to allow flexibility

Trailing edge (28) – taper to aid installation